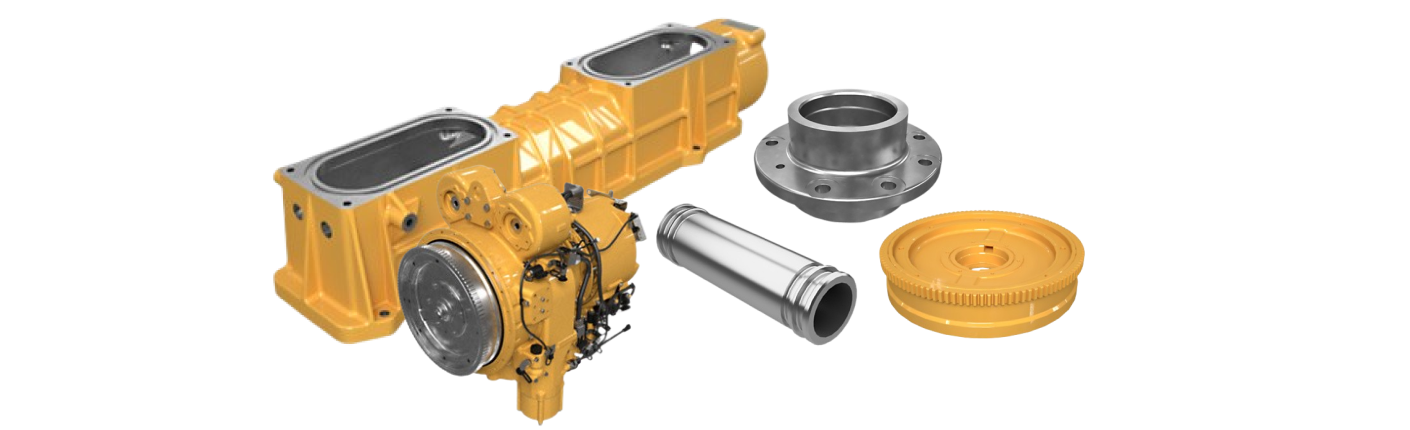

Engine shape: Built in 6-cylinder engine

Consumption: 8.9 liters

Horse: 230-400h p (L 72-298kW)

Maximum torque: 915-1627

Line diameter and route: 114145

Suction: turbocharged cooling

Oil system: 27.6 liters

Length * width * height: 112 5.2 * 1163.3 * 1183.6

Weight: 708 kg

The DC air filtration system is designed for the development of Platform 4, providing smaller, more flexible installation and higher air filtration efficiency.

XP I Fuel System - Provides precise fuel under ultra-high pressure.

Variable Geometry Turbocompressor (VGT) ™) - In improved response and control as well as electric drive programs, ensure precise propulsion, sliding nozzles, and improve reliability and durability throughout the entire working process.

Fully integrated electronic control - Da Rong provides electronic control module (ECM) control from consumption to exhaust gas to achieve optimal performance. Exhaust Gas Cooling Gain (EGR-RE) reduces combustion temperature to reduce emissions and optimize fuel efficiency.

Cummins particle filter integration, achieving maximum performance, can remove more than 90% of particles, specifically designed to resist the serious impact of non wood equipment.

The crankcase ventilation system - oil mist and droplets to maintain clean working conditions of the engine.

The lowest maintenance cost, longer maintenance intervals, better fuel efficiency, and guaranteed long-term service life.

A complete integrated electronic control system - Electronic Control Module (ECM) with high capability from intake to exhaust, achieving optimal performance. Used to seamlessly collect all components to optimize engine performance.